1.Brief Introduction

DGAC50 ac asynchronous motor roller is often applied in light and medium load converying .

Be Integrated with alternate direct asynchronous gear reduction motor.

Output torque has two types: AS(Standard Type) and HAS(High Torque Type).

Take winding protection motor design,motor does not broken down for long time locked rotor(only dia 50,60,As,Has).

Power supply: 3PH380V,3PH220V,1PH220V.

Three Phase motor can be adjusted speed with inverter.Speed Range:25HZ~65HZ(only 3PH220V)

Speed adjusting range: 2~52m/min

Tube Material:mild steel&galvanized,mild steel&rubber coated,mild steel&pu coated, SUS304.

Length can be customerized according to client’s request.

Roller type: Straight Roller,Body with O groove,O-Belt Pulley,V-Belt Pulley,Timing pulley, Poly V Pulley,Sprocket Pulley.

Installation is simple and convenient.

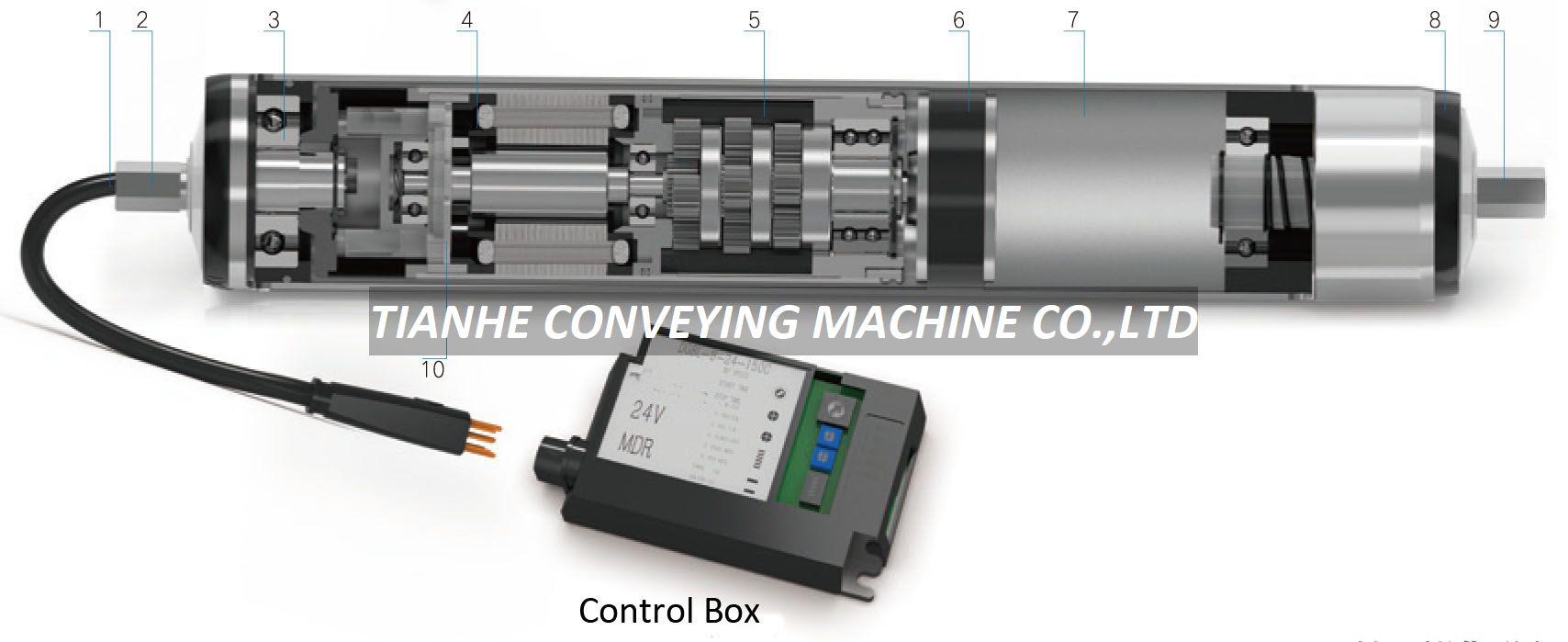

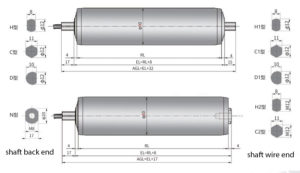

Motor Roller Profile Components Picture

1.Electric wire 2. Shaft end with electric wire 3.Front bearing house 4.Motor 5.Gear box 6.Fixed house 7.Tube

8.Back bearing house 9. the other shaft end 10.Hall chip

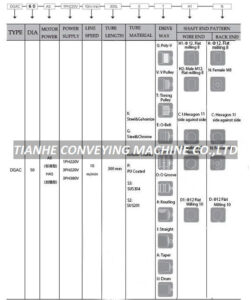

2.Model Selection

Note: 1.Other voltage and roller’s shape can be customized according to client’s request;

2.Special specifications: International Protection(IP65)—HS;Brake(mecahnical brake)-Z;

Accumulation(adjustable accumulation)—AU; Elastic shaft-TX.

Model Selection Example 1

DGAC60-AS-3PH220V-300L-10M/Min-X-I-C1N

Model Selection Example 2

DGAC60-HAS-3PH220V-300L-10M/Min-X-Q-C1C-Z

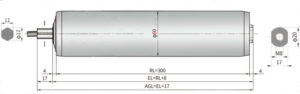

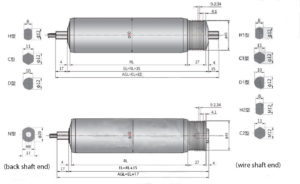

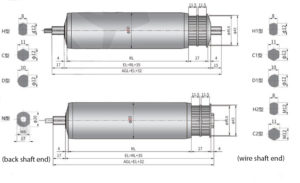

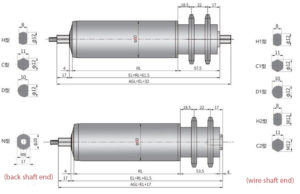

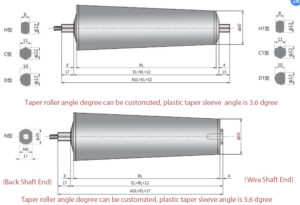

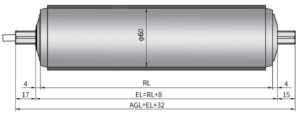

Motor Roller’s Shape Size Drawing

1).Straight Motor Roller

Φ60*1.5 mild Steel tube, Galvanized, Chrome Plated,SUS201 or SUS304

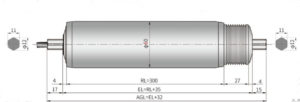

2).Poly-V Pulley Motor Roller

Poly-V pulley’s material is SUS304, Zinic Alloy,Nylon. 9 grooves, PJ Poly-V belt. working load:100kgs.

3).Timing Pulley Motor Roller

Timing Pulley can avoid slipping. Timing Pulley’s material is SUS304, Aluminum Alloy.

Timing Pulley’s Spec: 2 grooves, teeth type:T5, 26 tooth. Specail spec can be customized.

4).V Pulley Motor Roller

V Pulley’s material is SUS304,Aluminum Alloy. V Pulley type: Bando VC-6. Because V-belt is PU,so it

is quiet during running. This type of motor roller is suitable for light products conveying.

5).Sprocket Motor Roller

Sprocket’s Material is mild steel or SUS304. Double Sprocket, Sprocket type: 08B14T.

6).O Groove Motor Roller

O Groove: PU Belt is used on it. So, conveying is quiet. It is suitable for light product conveying. Working load:35kgs

If back shaft end is elastic shaft, O-Groove size is needed to check with us.

7).O Belt Pulley Motor Roller

Material of O Belt Pulley is Nylon,PU Belt is used for it. It is suitable for light products conveying.

Working Load is bigger than O Groove Motor Roller.

8).Taper Motor Roller

It is used for curve conveying. it can be made by some plastic taper sleeves or can be made by mild steel or SUS304.

9).Coated Motor Roller

Coated Material is rubber or PU. Diameter is Ø65mm coated from Ø60mm.

Coating purpose is avoiding slipping, increasing friction on contacting area and protect bottom of conveying product.

Soft PVC Sleeve.Diameter is Ø64mm after applying soft pvc sleeve based on Ø60mm .

It has almost same funcitons as Coated Motor Roller. At he same time, it has short time lead time and low price.

10).Knurling Motor Roller

Knurling is for increasing friction of conveying products. Roller surface pattern is mesh type.

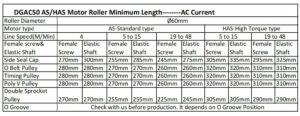

3.DGAC60 AS/HAS external minimum roller comparison table

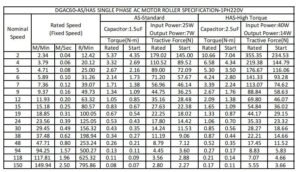

4.DGAC60 AS/HAS Alternate Current Motor Roller Specification:

1). 1N=0.1kgf, 1N·M=0.1kgf·m;

2).Above parameters is only for you reference;

3).Rated Speed is the speed which is under rated voltage and rated power;

4).Fixed speed can not be adjusted;

5).Other speed can be customized;If you need more faster motor roller, please refer to DGDD50

direct drive style;

6).Sprocket driving parameters can be used by above parameters;

Poly-V driving, single driving unit can not be more than 100kgs;

O-belt driving,single driving unit can not be more than 35kgs.